+86-750-3598205

+86-750-3598205

In the rapidly evolving landscape of lighting design, selecting the right Led Extrusion is crucial for ensuring optimal performance and aesthetics in any project. According to industry expert Dr. Emily Tran, a renowned lighting technology consultant, "Choosing the appropriate Led Extrusion can not only enhance the visual appeal of a space but also improve energy efficiency and longevity of the lighting solution." As we move into 2025, understanding the various types of Led Extrusions available in the market is essential for designers and architects alike.

The versatility of Led Extrusions enables them to be integrated into a myriad of applications, from residential settings to commercial environments. With advances in technology and materials, professionals can now select from a range of options that cater to different illumination needs and design preferences. In this informative guide, we will explore the key factors to consider when choosing Led Extrusion for your lighting project, ensuring that you make an informed decision that meets both your functional requirements and aesthetic goals.

Understanding LED extrusions is crucial for optimizing lighting design in various applications, from residential to commercial settings. These extrusions serve as protective housings for LED strips, providing not only a sleek and professional finish but also enhancing the thermal management of the LEDs. By dissipating heat effectively, LED extrusions extend the lifespan of the lights, ensuring consistent performance over time. Additionally, they help diffuse the light emitted from the strips, allowing for an even distribution that minimizes harsh shadows and glare while creating an inviting atmosphere.

When choosing LED extrusions, it's important to consider various factors such as material, shape, and installation method. Common materials include aluminum, which offers excellent heat dispersion, and polycarbonate for added durability and versatility in design. The shape of the extrusion can impact the light angle and aesthetic appeal of a lighting project. Options range from slim profiles for discreet applications to bulkier designs for more dramatic effects. By understanding these elements, designers and builders can select LED extrusions that not only fit the technical requirements of their project but also align with the overall vision and style of the space.

When selecting LED extrusions for your lighting project in 2025, several key factors come into play. First and foremost, consider the material of the extrusion. Aluminum is a popular choice due to its excellent thermal conductivity, which can enhance the lifespan and performance of LED lights. According to a recent report from the Global Lighting Association, projects using high-quality aluminum extrusions can see a decrease in thermal management issues by up to 30%. This can lead to increased efficiency and reduced maintenance costs over time.

Another critical factor to evaluate is the profile design of the extrusion. Different applications may require specific shapes to achieve the desired illumination and aesthetic appeal. A study published in the Journal of Architectural Lighting found that well-designed profiles can improve light distribution by as much as 25%. For instance, if you’re illuminating a workspace, opt for designs that minimize glare while maximizing light output.

**Tips:** Always assess the compatibility of your LED strip with the extrusion. Ensure that the dimensions allow for easy installation and that the cooling features align with the LED’s thermal requirements. Additionally, consider the finish of the extrusion; a matte surface can enhance light diffusion, creating a more uniform lighting effect. Before committing to a choice, consulting with a lighting design professional can provide insights tailored to your specific project needs.

When selecting the right LED extrusion for your lighting project, it's essential to understand the various types available and their unique characteristics.

LED extrusions come in various profiles, such as surface-mounted, recessed, and pendant styles, each offering different aesthetics and installation options. Surface-mounted extrusions are ideal for adding a modern touch to ceilings or walls, while recessed options provide a sleek, integrated look within fixtures. Pendant extrusions can bring a statement piece to any space, highlighting specific areas or artwork.

Tips for selecting the ideal LED extrusion include considering the intended application and the environment where the lighting will be installed. For instance, if the project involves a damp area like a bathroom or outdoor space, opt for extrusions with weatherproof and moisture-resistant properties. Additionally, think about the light diffusion required; frosted covers can soften beam spread, whereas clear covers maximize light output.

Lastly, assess the ease of installation. Some extrusions come with mounting clips or integrated hardware, simplifying the installation process. Choosing LED extrusions with adaptable features and accessories can also enhance your design flexibility, ensuring your lighting project stands out and meets both aesthetic and functional goals.

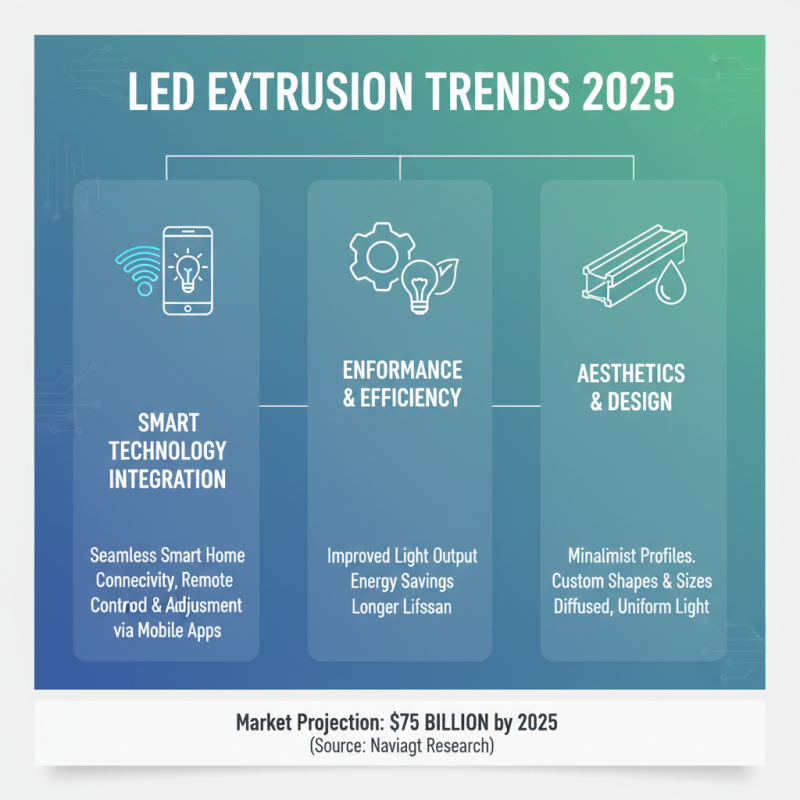

When selecting LED extrusion for your lighting project in 2025, it's vital to focus on innovative features that enhance performance, energy efficiency, and aesthetics. One of the key trends for this year is the integration of smart technology. According to a recent industry report by Navigant Research, smart lighting systems are projected to reach a market size of $75 billion by 2025, indicating a significant shift towards IoT-enabled solutions. Look for LED extrusions that provide seamless connectivity with smart home systems, allowing for remote control, dimming, and color adjustments through mobile apps.

Another important feature is the emphasis on sustainability. With increasing awareness of environmental issues, LED extrusion products that utilize recyclable materials and have longer lifespans are becoming essential. A study from the U.S. Department of Energy reveals that high-quality LED products can last up to 25 times longer than traditional lighting options, drastically reducing waste over time. Therefore, prioritize purchasing options that highlight eco-friendly practices, including low energy consumption and recyclable components.

Tips: When evaluating different LED extrusion options, consider the lumen output per watt to ensure optimal brightness and efficiency. Additionally, pay attention to the color rendering index (CRI); a higher CRI means better color accuracy, which is crucial for applications like retail or art galleries. Always review product specifications to find the best fit for your specific lighting needs.

When it comes to installing LED extrusions, following best practices is essential for achieving optimal results while ensuring safety. Begin by planning your layout meticulously. Consider both the aesthetic appeal and functionality of the lighting in your space. Using a marked diagram can assist in visualizing where the extrusions will be installed and how the light will play off various surfaces.

Tips: Always measure twice and cut once to avoid errors that could lead to wasted materials. Ensure you have the right tools, including a level for precision, which is crucial for achieving a professional finish. Additionally, account for the power source and ensure that it is easily accessible for maintenance.

When installing LED extrusions, it's important to follow safety precautions. Wearing protective gear such as gloves and safety goggles can prevent injuries from sharp edges and debris. Ensure the current to the electrical supply is turned off before installation, and consult an electrician if you are unsure about any electrical aspects of your project.

Tips: Make sure to use appropriate fasteners and adhesives designed for LED installations, as using the wrong materials can lead to damage or faulty lighting. Careful planning and execution can enhance your lighting project, making it both visually appealing and safe for all users.