+86-750-3598205

+86-750-3598205

In the ever-evolving world of LED extrusion, efficiency is crucial for maximizing productivity and minimizing waste. Industry expert Dr. Emily Carter, a leading researcher in polymer engineering, emphasizes the significance of mastering this process: "To stay ahead in the LED extrusion industry, adopting innovative techniques and best practices is essential." Her insight sheds light on the challenges and opportunities presented by LED extrusion, where precision in design and execution can lead to remarkable advancements in lighting technology.

As the demand for energy-efficient lighting solutions continues to grow, understanding the intricacies of LED extrusion becomes increasingly vital. This process not only involves the careful selection of materials but also requires the application of advanced extrusion methodologies. In this article, we will explore the top 10 tips for efficient LED extrusion processes that can help manufacturers optimize their operations and deliver high-quality products. By integrating these strategies, companies can enhance their production capabilities, reduce costs, and ultimately contribute to a more sustainable future in the lighting industry.

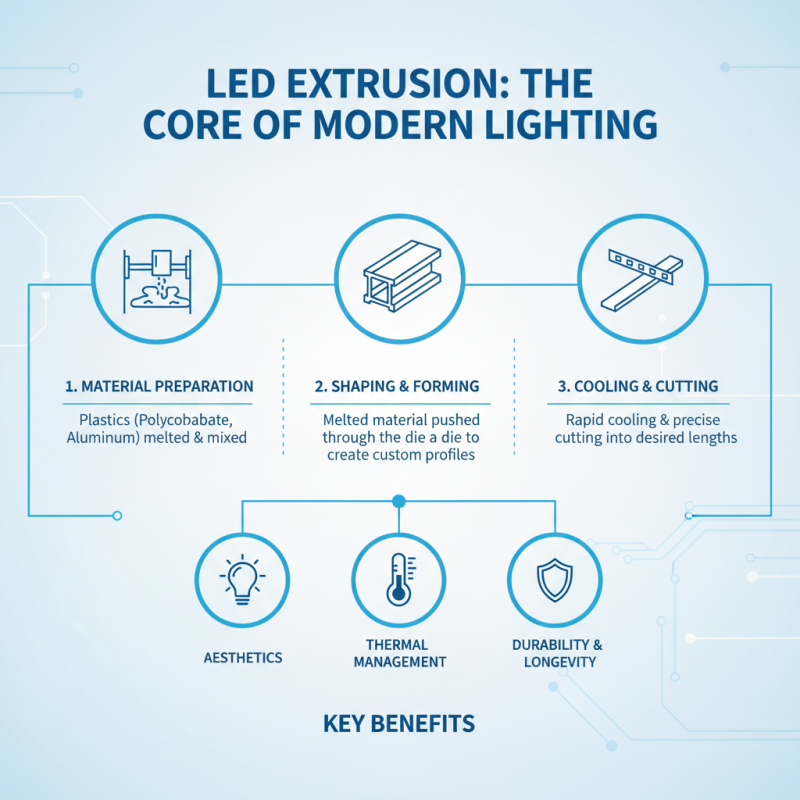

LED extrusion is a pivotal process in the manufacturing of LED lighting solutions, which has gained significant importance in the pursuit of efficient and high-performance lighting technologies. At its core, LED extrusion involves the shaping of materials, typically plastics, into specific forms that can house LED components. This process not only influences the aesthetic appeal of the final product but also its thermal management and overall durability, which are crucial for ensuring longevity and optimal performance in various applications.

Understanding the principles of LED extrusion can greatly enhance production efficiency and product quality. Key factors such as temperature control, material selection, and die design play integral roles in the extrusion process. Proper temperature regulation ensures that the materials are adequately heated to facilitate smooth flow and molding, while the choice of raw materials can affect light diffusion and heat dissipation. Moreover, a well-engineered die design can significantly reduce the likelihood of defects, ensuring a consistent and uniform extrusion. These foundational aspects underscore the importance of a well-planned LED extrusion process, which ultimately contributes to the successful development of cutting-edge LED lighting solutions for diverse environments.

When it comes to optimizing LED extrusion processes, several key factors can significantly impact efficiency. Understanding these elements can help streamline production and enhance the quality of the final product. One critical factor is temperature control; maintaining an optimal processing temperature ensures that the materials flow smoothly through the extruder. Excessive heat can lead to degradation of the materials, while too little heat can cause blockages. Regular monitoring and adjustments can prevent these issues and contribute to smoother operations.

Another important aspect is the choice of materials and their compatibility with the extrusion process. High-quality raw materials that are specifically formulated for LED applications tend to yield better results in terms of clarity, diffusion, and color consistency. Incorporating additives that improve flow characteristics can also enhance the extrusion efficiency.

To maximize efficiency, consider implementing regular maintenance schedules for machinery. Well-maintained equipment tends to operate more reliably and predictably, reducing downtime and waste. Additionally, leveraging automation technologies can streamline processes, from loading materials to monitoring extrusion outputs, ultimately leading to a more efficient operation.

Selecting the right materials for LED extrusion is crucial to achieving optimal performance and efficiency. When considering material selection, it’s essential to look for thermoplastics with excellent optical clarity and good UV stability. Polymers like polycarbonate and acrylic are commonly favored for their ability to withstand environmental stressors while maintaining transparency. This choice not only affects the quality of light diffusion but also the longevity of the LED products.

Incorporating efficient extrusion practices can enhance the overall outcome. For instance, maintaining precise temperature control during the extrusion process ensures uniform melting and helps prevent defects, which is especially important when using advanced materials. Additionally, the use of additives can significantly improve processing characteristics, such as enhancing flow or modifying mechanical properties, allowing for a smoother extrusion flow while preserving the necessary thermal and electrical properties.

Ultimately, understanding the specific requirements of the LED application will guide material selection and extrusion techniques. By prioritizing materials that offer both durability and aesthetic quality, manufacturers can streamline their production processes while delivering high-performing LED products to the market.

| Dimension | Recommended Values | Comments |

|---|---|---|

| Material Type | Polycarbonate & PMMA | High transparency and impact resistance |

| Extrusion Temperature | 200-250°C | Optimal for most materials |

| Cooling Rate | Moderate (Air vs. Water) | Fast cooling improves surface finish |

| Melt Flow Index | 5-20 g/10 min | Higher values ensure better flow |

| Additives | UV Stabilizers, Colorants | Enhances longevity and aesthetics |

| Die Design | Flat or round die | Influences the final product shape |

| Extrusion Speed | 5-20 m/min | Adjust according to material |

| Post-Processing | Cutting, Polishing | Essential for quality finish |

| Quality Control | Regular checks | Ensure dimensional accuracy |

| Energy Efficiency | Low energy consumption | Increases overall profitability |

Optimizing machine settings is crucial for enhancing the performance of LED extrusion processes. Research indicates that even minor adjustments in temperature can significantly impact the quality and efficiency of the final product. According to a study published by the International Plastics Association, maintaining an extrusion temperature of around 200-220°C helps in achieving optimal flow properties for thermoplastics used in LED applications. Ensuring a precise thermal profile not only improves the visual clarity of LED encapsulants but also enhances their thermal stability, resulting in better light output and longevity.

Moreover, the screw design and speed play a pivotal role in extrusion efficiency. The same report highlights that using a screw with a proper compression ratio can increase the melt quality and reduce shear degradation, which is vital when processing sensitive LED materials. By fine-tuning the screw speed, manufacturers can also optimize the residence time of the material in the barrel, allowing for uniform melting and mixing. Studies indicate that maintaining a screw speed within a range of 50-150 RPM can improve the throughput by up to 20%, thereby maximizing productivity without compromising product integrity.

Additionally, employing real-time monitoring systems for parameters like pressure and melt flow can further enhance performance. The implementation of Industry 4.0 technologies allows for immediate feedback and adjustments, ensuring that deviations from optimal settings can be corrected promptly. This approach can reduce material waste significantly, as supported by a report from the Global Manufacturing Forum, which found that real-time adjustments can cut down production errors by as much as 30%. By focusing on these machine settings, manufacturers can elevate their LED extrusion processes to achieve higher quality outputs and increased operational efficiency.

In the LED extrusion process, common issues can significantly impact both productivity and quality. One prevalent challenge is the inconsistency in material feed, which can lead to uneven extrusions. To troubleshoot this, it is crucial to ensure that the feed system is well-calibrated and that the materials are dry and free of contaminants. Routine checks on hopper levels and the proper functioning of the auger can help maintain a steady flow, preventing defects in the final product.

Another frequent issue arises from temperature regulation within the extrusion system. If the extruder temperature is not properly calibrated, it can result in inadequate melting or overheating of the polymer, leading to poor optical properties or structural integrity of the LED components. Utilizing thermocouples and digital temperature controllers can enhance monitoring accuracy. Furthermore, regular maintenance of heating elements is essential to avoid temperature discrepancies that could compromise the extrusion quality. By addressing these typical issues, manufacturers can optimize their LED extrusion processes and enhance product reliability.