+86-750-3598205

+86-750-3598205

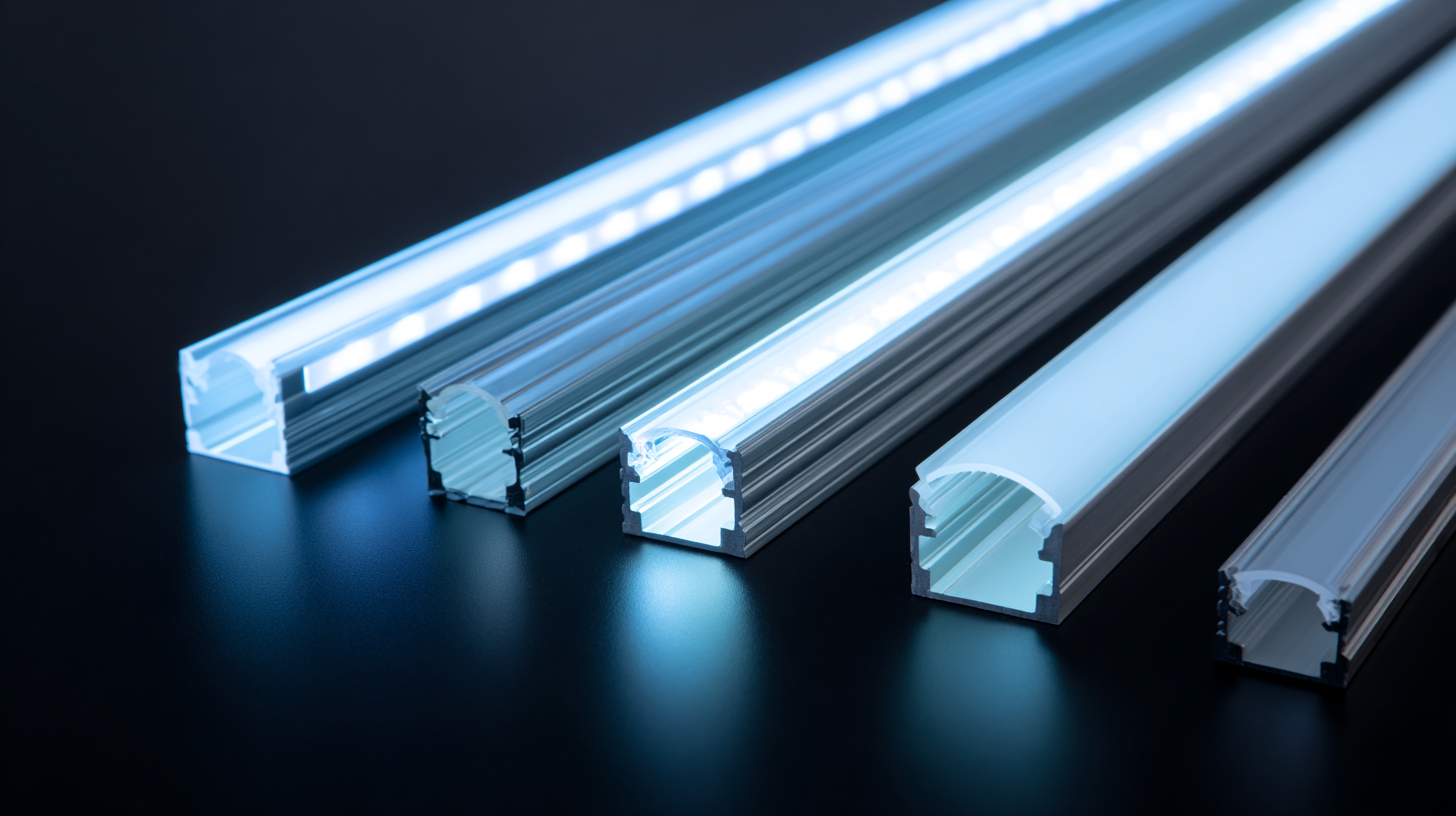

In the rapidly evolving world of lighting technology, the field of Led Extrusion stands at the forefront of innovation and efficiency. As we look ahead to 2025, industry experts are keenly observing the emerging trends that promise to redefine how we illuminate our spaces. According to Dr. Emily Chen, a leading authority in the Led Extrusion industry, "The future of lighting lies in our ability to blend functionality with creativity, and Led Extrusion is the key to unlocking this potential." Her insights highlight the transformative impact of advancements in this sector.

The continued development of Led Extrusion technology not only enhances lighting efficiency but also opens the door to new design possibilities that cater to diverse aesthetic and functional needs. Trends such as the integration of smart controls, customizable profiles, and sustainable materials are set to be at the forefront, driving both innovation and energy savings. As we delve into the top 10 trends shaping the Led Extrusion landscape, it becomes evident that the confluence of creativity and technology is paving the way for a brighter and more sustainable future.

The landscape of LED extrusion is rapidly evolving, particularly with the advent of emerging materials and innovative techniques aimed at enhancing light output. Reports from industry leaders indicate that the use of advanced polymers, such as polycarbonate and thermoplastic elastomers, is becoming more prevalent, allowing for greater design flexibility and improved durability. According to a 2023 study by LED Magazine, these new materials can improve light transmission efficiency by up to 20%, which significantly boosts overall lighting performance.

In addition to material innovation, the integration of advanced extrusion techniques like co-extrusion and 3D printing is set to redefine manufacturing processes. These methods enable the production of complex geometries and customized profiles that optimize light distribution while minimizing waste. A recent market analysis published by Research and Markets predicts a compound annual growth rate of 12% for LED extrusion technologies through 2025, highlighting the sector's burgeoning potential.

**Tip:** When selecting materials for LED extrusion, consider not just the light output but also factors such as heat resistance and UV stability to ensure longevity and reliability of the fixtures.

**Tip:** Embrace the latest extrusion technologies. Techniques such as intelligent extrusion allow for the production of multifunctional LED components that can integrate optics and thermal management, thereby enhancing efficiency further.

The landscape of LED extrusion is transforming as innovative design trends emerge to enhance lighting efficiency and aesthetic appeal. One of the most significant trends is the integration of smart technology within LED extrusion designs. This innovation allows for dynamic adjustments in lighting based on user preferences and environmental conditions, paving the way for more energy-efficient solutions. Smart systems equipped with sensors can adapt to levels of natural light, reducing energy consumption while maintaining optimal brightness.

In addition, the emphasis on sustainability is driving creativity in LED extrusion designs. Manufacturers are increasingly exploring eco-friendly materials and manufacturing processes. This trend not only helps in reducing the carbon footprint but also appeals to environmentally conscious consumers. Designs that incorporate modular components allow for easy upgrades and repairs, promoting longevity and reducing waste. As architects and designers seek to create versatile lighting solutions, these innovative trends in LED extrusion are set to redefine the way we illuminate our spaces, making them more efficient and aesthetically pleasing.

Maximizing energy efficiency in LED lighting technology has become a pivotal focus for industries aiming to reduce operational costs and environmental impact. According to the U.S. Department of Energy, LED lighting consumes up to 75% less energy than traditional incandescent bulbs and lasts 25 times longer, translating into significant savings over time. This shift is not just about replacing bulbs; it's about adopting advanced LED extrusion technologies that enhance the distribution and intensity of light while minimizing energy waste.

Tip: Implementing smart controls in conjunction with LED systems can further amplify energy savings. These controls can adjust lighting based on occupancy and natural light levels, resulting in an additional 30% energy savings on top of what LEDs already provide.

Moreover, the move towards sustainable materials and innovative designs in LED extrusion is shaping the future of lighting. The use of aluminum and polycarbonate in extrusion processes allows for better thermal management, which enhances the lifespan and efficiency of lighting fixtures. A report from Grand View Research indicates that the global LED market is projected to reach $137 billion by 2028, driven primarily by innovations in energy-efficient lighting solutions.

Tip: Regularly updating your lighting infrastructure with the latest LED technology and materials can ensure optimal performance and sustain long-term energy savings, aligning with the industry's rapid advancements.

This chart illustrates the key trends in LED extrusion for 2025, with a focus on energy efficiency and innovation. The data shows the importance of various aspects such as Energy Efficiency, Innovative Designs, Extended Lifespan, Cost-Effectiveness, and Eco-Friendliness, rated on a scale of 1 to 10.

The integration of smart technology into LED extrusion processes is set to revolutionize the lighting industry by significantly enhancing efficiency and innovation. One of the most prominent advancements in this area is the adoption of Internet of Things (IoT) capabilities in LED extrusion machinery. By connecting these machines to a centralized network, manufacturers can remotely monitor production workflows, optimize energy consumption, and predict maintenance needs. This connectivity not only reduces downtime but also allows for real-time adjustments to the extrusion process, ensuring that lighting products meet precise quality standards.

Furthermore, smart technology in LED extrusion is enabling a new level of customization. With advanced data analytics and machine learning algorithms, manufacturers are now able to tailor lighting solutions to specific consumer needs. For instance, extrusion lines can be programmed to produce LED profiles with varying lumens and color temperatures based on market demand, allowing for a quicker response to changing trends. This synergy between smart technology and LED extrusion processes not only enhances product innovation but also supports sustainable practices by minimizing waste and energy use during production.

In recent years, sustainability has become a cornerstone of manufacturing practices within the LED extrusion industry. As manufacturers strive to minimize their environmental impact, techniques such as using recycled materials and adopting energy-efficient processes have gained traction. This shift not only enhances the overall efficiency of LED lighting systems but also caters to a growing consumer demand for eco-friendly products. Companies are investing in technologies that reduce waste and energy consumption during production, paving the way for innovative designs that utilize sustainable resources.

Tips for adopting sustainable practices in LED extrusion include collaborating with suppliers who prioritize eco-friendly materials, which can significantly boost the sustainability quotient of the final product. Additionally, implementing energy-efficient machinery and optimizing production processes can drastically cut down on operational waste. Regularly assessing and updating manufacturing techniques will ensure ongoing compliance with sustainability standards while enhancing overall product quality.

Moreover, embracing circular economy principles, where products are designed for reuse and recycling, can further enhance the sustainability profile of LED extrusions. This approach not only supports environmental goals but also opens new markets for businesses committed to responsible manufacturing. By focusing on sustainability, companies can create a positive impact on both the planet and their bottom line, ensuring long-term success in the competitive LED market.