+86-750-3598205

+86-750-3598205

In the evolving world of lighting technology, Led Extrusion stands out as a revolutionary technique. Robert Lin, a leading expert in the field, once stated, "Led Extrusion enables unique designs that traditional methods cannot achieve." His insight reflects the core value of this method.

Led Extrusion combines design freedom with functional efficiency. This process allows for smooth integration of LED lights into various materials. However, not every extrusion process leads to ideal results. Factors like temperature and pressure need careful control to avoid imperfections. Some manufacturers overlook these details, resulting in less than optimal performance.

Exploring Led Extrusion reveals its advantages, but challenges remain. Understanding these elements can enhance product quality. By focusing on both the benefits and potential pitfalls, we can improve the industry. The journey to mastering Led Extrusion involves learning from past mistakes. Each step presents a chance to refine techniques, ultimately delivering brighter innovations.

LED extrusion techniques offer innovative lighting solutions for various applications. These methods involve creating channels to house LED strips while providing protection and enhancing light diffusion. There are a few prominent techniques that users should consider when designing effective lighting solutions.

One popular technique is aluminum extrusion. It provides a sturdy structure that dissipates heat effectively. This process allows for a sleek look, suitable for modern spaces. Another common method is using polycarbonate or acrylic materials, which are often chosen for their transparency and flexibility. They enable creative designs, including curved or customized shapes. However, challenges can arise, such as potential light leakage and dimming effects, which may require adjustments during installation.

For outdoor applications, weather-resistant extrusion techniques are vital. They ensure that lighting fixtures withstand harsh conditions. Yet, despite these advancements, some users struggle with selecting the right materials. Mistakes in choosing the wrong extrusion can lead to inadequate lighting performance. It's essential to research and reflect on previous projects to improve future outcomes. Understanding the nuances of different techniques can lead to better lighting solutions.

LED extrusion brings significant benefits to modern lighting design. This technique protects LEDs, ensuring durability while enhancing aesthetic appeal. The extrusions help disperse heat, extending the lifespan of the lighting system. According to industry reports, LEDs can last up to 25 times longer than traditional bulbs. This reliability translates into less frequent replacements and reduced maintenance costs.

Using LED extrusion also improves energy efficiency. A well-designed extrusion can enhance light output by 30%. This means better illumination with lower energy consumption. In a world where energy costs are rising, LED technology stands out. Additionally, extrusion allows for creative designs, integrating lighting into various architectural styles.

Tips: Choose the right material for your extrusion. Different plastics offer varied optical effects and durability levels. Pay attention to the color temperature of your LEDs. This decision impacts mood and ambiance. Remember some extrusions can be challenging to install. Proper planning is crucial to avoid misalignment or lapses in performance.

Don’t overlook potential downsides. Improper extrusion design may lead to hotspots or uneven light distribution. It's essential to select the right diffusion methods. Ultimately, striking a balance between functionality and design is key.

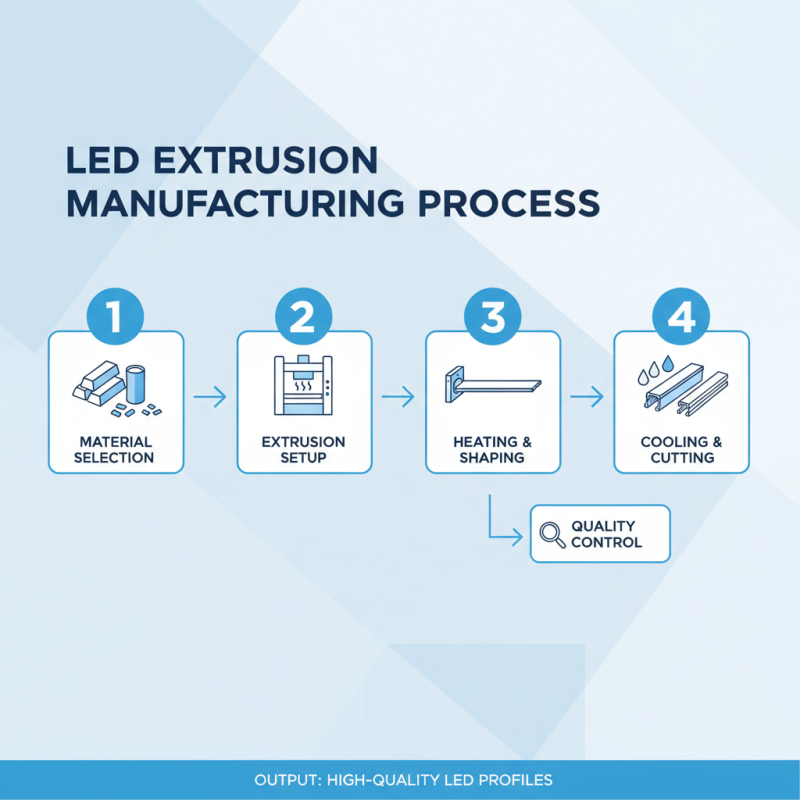

LED extrusion manufacturing is a precise process. It combines raw materials through heating and shaping. The aim is to create high-quality LED profiles. Key steps include material selection, extrusion setup, and cooling.

Material selection is crucial. Certain plastics perform better than others. They must withstand heat and provide durability. The extrusion setup involves machine calibration. Operators need to monitor temperatures and pressures closely. Small adjustments can impact the quality of the final product. By optimizing these settings, manufacturers can reduce waste.

After extrusion, cooling methods are important. Cooling too quickly can cause defects. Each profile must be inspected for flaws. This often leads to discussions about potential improvements. Understanding the entire process helps teams refine their techniques. Continuous learning is essential in this industry.

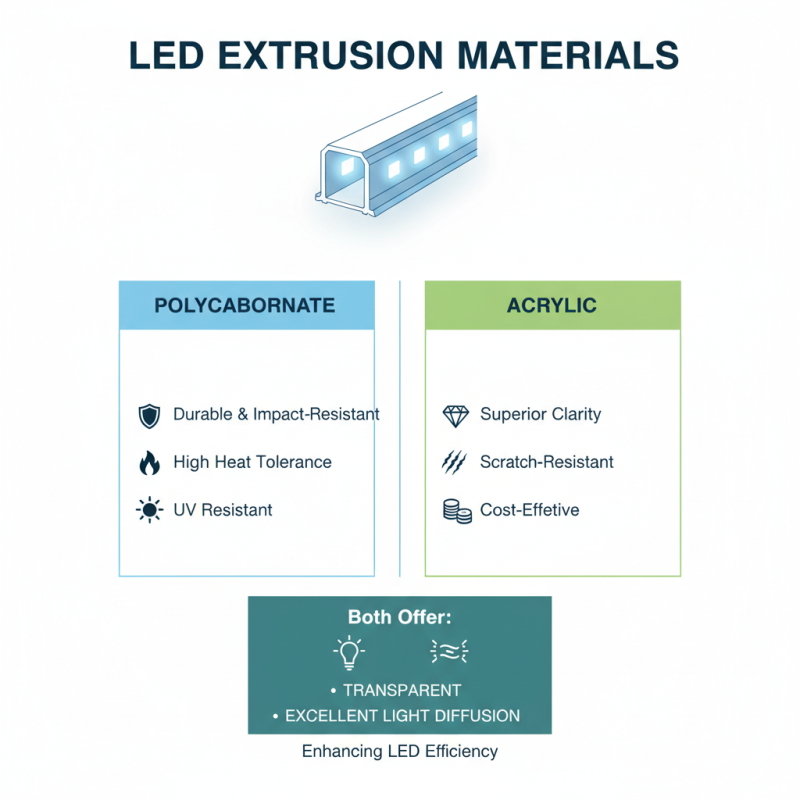

LED extrusion is a process that shapes materials for efficient lighting solutions. The production relies heavily on specific materials that influence performance and durability. Polycarbonate and acrylic are two common choices. Both materials are transparent and provide excellent light diffusion, enhancing LED efficiency.

Choosing the right materials is crucial. Polycarbonate is lightweight and impact-resistant. It can endure extreme temperatures. This durability, however, comes with a price. It can be more challenging to mold than other options. Acrylic, on the other hand, is easier to work with. It offers high clarity but can be less robust. This trade-off should be carefully considered.

There’s also the need for additives, which modify material properties. UV stabilizers, for example, protect against sunlight degradation. However, finding the right balance of additives can be tricky. Too much can hinder transparency, while too little may not offer adequate protection. These complexities highlight the importance of material selection in LED extrusion production.

LED extrusion is transforming various industries with its innovative applications. In architecture, LED extrusion lighting fixtures enhance spaces, providing both functionality and aesthetics. According to a report by Research and Markets, the global LED lighting market is expected to reach $130 billion by 2026. This shows a growing trend towards LED technology due to its energy efficiency and longevity.

In retail, stores are adopting LED extrusion to create immersive shopping experiences. Stores use LED strips to highlight products, leading to increased sales. A Nielsen study found that consumers are 55% more likely to shop in a well-lit environment. However, despite the benefits, some retailers struggle with installation complexities and maintenance issues.

The automotive industry leverages LED extrusion for interior and exterior lighting solutions. Enhanced visibility and safety are key advantages. However, the high cost of advanced LED systems can be a barrier for some manufacturers. The industry's shift towards electric vehicles increases demand for sophisticated lighting technologies. This can challenge traditional practices and requires adaptation.